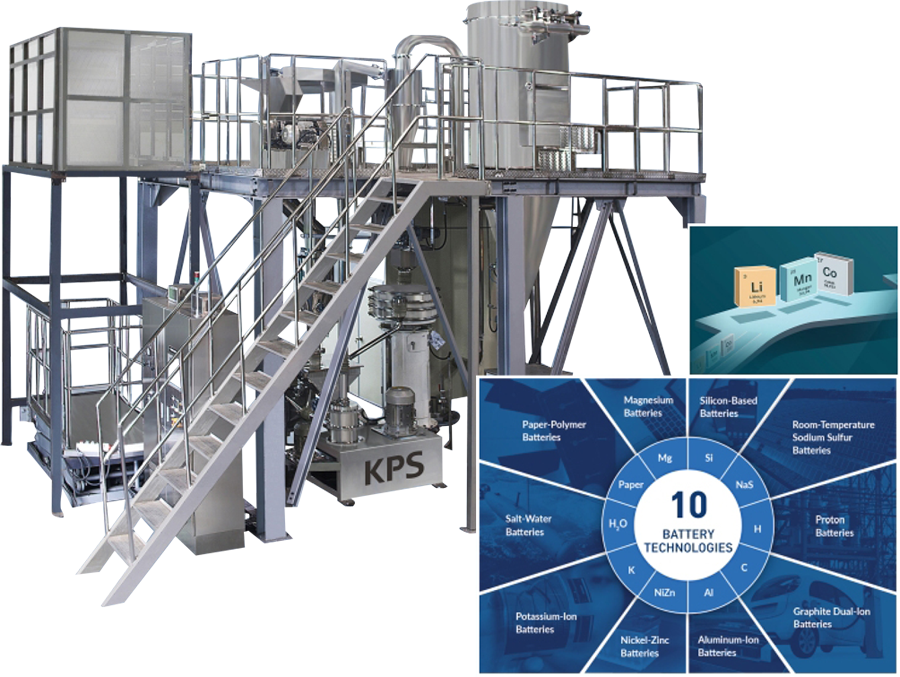

제품소개 KOREA POWDER SYSTEM

2차전지 재활용시스템

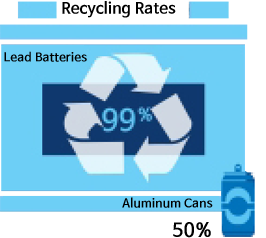

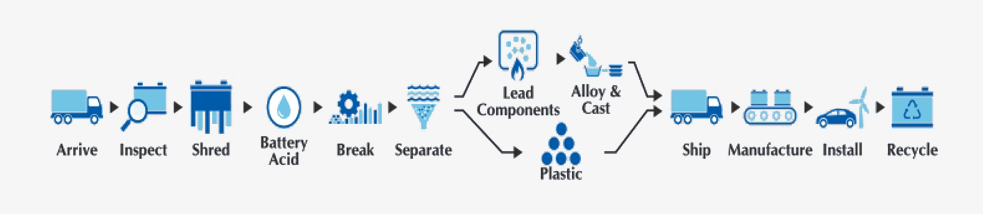

LEAD BATTERIES

Most Recycled Consumer Product

Lead batteries reign as the most recycled consumer product. 99% of batteries are safely recycled in an established

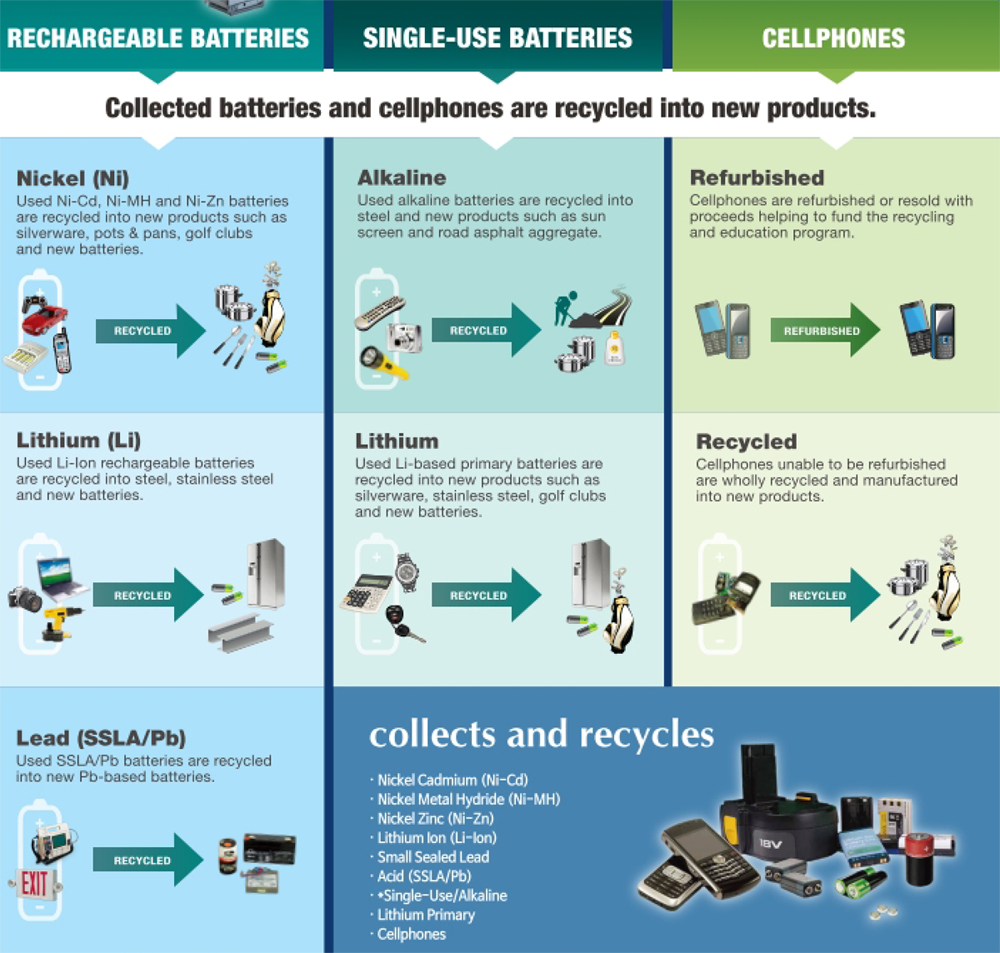

Batteries are in demand worldwide as storage media for renewable energies. But as production increases, so does the need for recycling methods that both recover the maximum amount of raw materials and ensure the highest level of safety for people and the environment.

KPS has developed a new, innovative process that efficiently recovers copper, lithium, nickel, cobalt, and aluminum in an environmentally friendly manner. Safety is of utmost importance. This is ensured by a gas-tight process in a protective atmosphere-which also requires considerably less energy than conventional methods.

KPS has developed a new, innovative process that efficiently recovers copper, lithium, nickel, cobalt, and aluminum in an environmentally friendly manner. Safety is of utmost importance. This is ensured by a gas-tight process in a protective atmosphere-which also requires considerably less energy than conventional methods.

Advantages

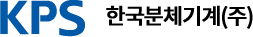

- Models are available in different sizes: modular design for small throughputs

- High process reliability and compliance with all occupational health and safety standards

- Maximum yield of raw materials, even aluminum, graphite, and lithium

- Global service

Recycling Process

- The challenge of battery recycling Sparking hazards, toxic components, and the wide variety of materials used make recycling batteries a challenge. KPS has developed an inno-vative recycling process that, unlike the approaches commonly used to date, ensures you do not have to compromise on safety, environmental protection, or cost-effectiveness.

- Recovering high-quality raw materials The new process lets you obtain marketable, high-quality end products, such as aluminum concentrates, copper concentrates, and black mass. The latter contains graphite, lithium, or various other metals such as manganese, cobalt, and nickel. Condensed electrolyte accumulates separately in our system and can thus easily be sent on for further trea" -tment or disposal.

- Safety is our number one goal KPS offers appropriate solutions for shredding feed material - whether cells, battery modules, or even battery packs. The process takes place, in a protective (inert) atmosphere in order to eliminate the risk of fire, and leakage of toxic substances. The gas-tight design of the machines reliably prevents leakage.

- Customized solutions Our plants and all process stages can be scaled to meet customer re-quirements - from 25 kg up to several metric tons per hour. Allagg -regates are adapted to the customer's specific needs. The modular design of plants for low throughputs ensures flexible implementation Our process and recycling experts conduct trials in our own test center to determine the optimum process for maximum yield.